Wenbin Li, Ph.D.

R&D Engineer at Flexiv Robotics

Biography

I received my PhD degree in May 2019 and was named as the College of Engineering and Computing Dean’s Ph.D. Scholar at Missouri University of Science and Technology (Missouri S&T).

I studied in the Innovative Smart and Additive Manufacturing Laboratory at Missouri S&T, advised by Dr. Ming C. Leu and co-advised by Dr. Greg Hilmas and Dr. Robert Landers. My PhD research was focused on Additive Manufacturing (AM, or 3D-Printing), especially, developing 3D-Printing apparatus and process for AM of ceramics.

Before I joined Missouri S&T, I received my MS and BS in Mechanical Engineering at Beijing Institute of Technology (BIT). I studied mechatronics in the Mechatronics Center and Intelligent Vehicle Research Center (IVRC) at BIT.

I am a lifelong learner, and passionate about all kinds of new technology like 3D Printing, Robotics, Engineering Materials, etc.

Interests

- Mechatronics, Electro-mechanical Automation

- Mechanical Design

- Additive Manufacturing (3D-Printing)

- Embedded Systems

- Ceramics

- Engineering Materials

- Robotics

- Robotic Grasping

- Adhesion

Links

- NEWS Our article is highlighted by advanceseng.com (Advances in Engineering)Details

- NEWS I am calling for ceramic AM related papers submitted to the Journal of Visualized Experiments (JoVE)! Details

- STORY Wenbin authored a WeChat article on Extrusion-based Ceramic 3D Printing. Details(CN)

- STORY Our research progress was reported by 3DPrint.com. Details

- STORY Wenbin was named as Dean’s PhD Scholar. Details

Projects

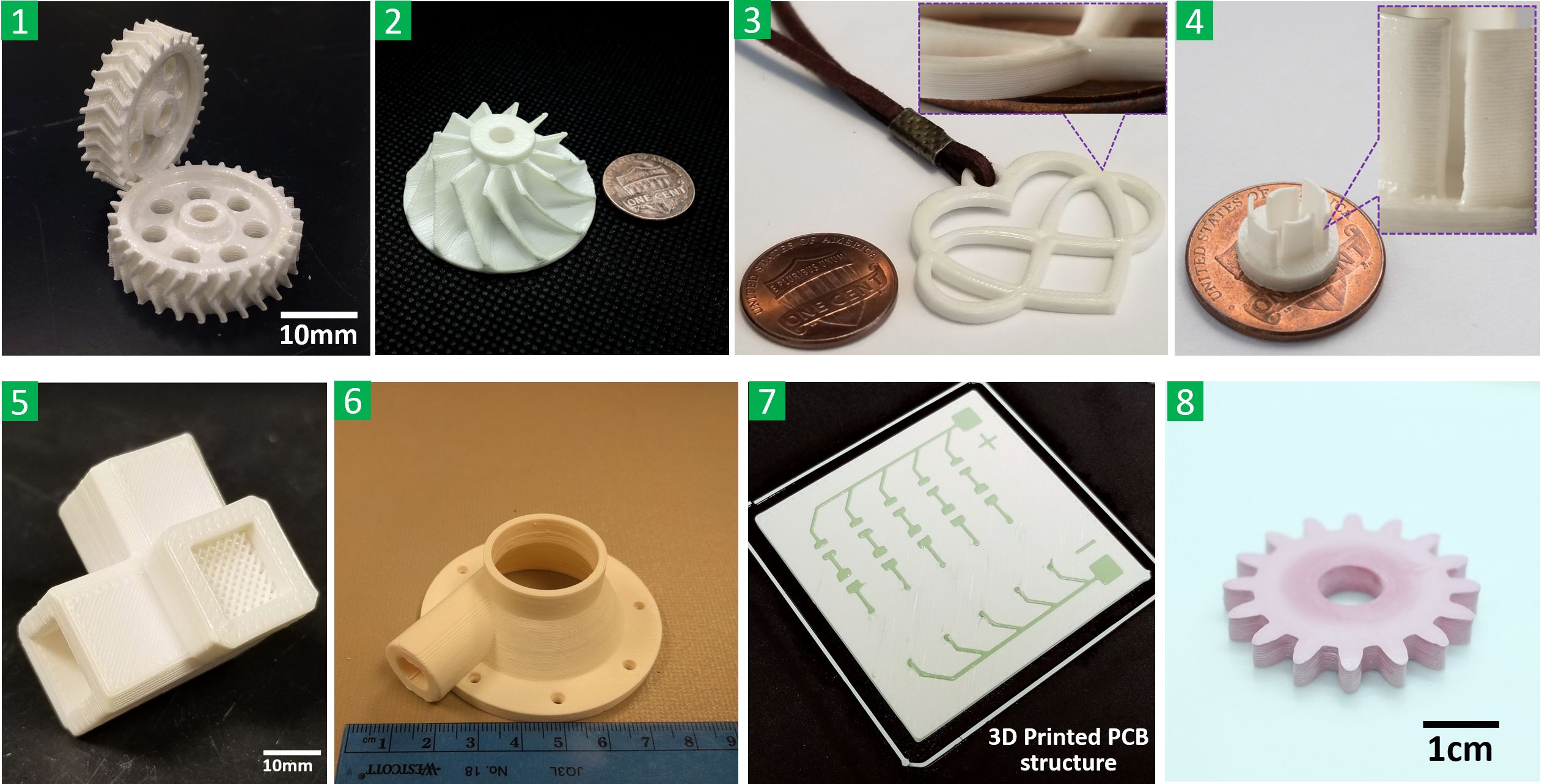

Additive Manufacturing (AM) of Ceramic and Ceramic Composites

Advanced ceramics are important engineering materials due to their superior performance in hardness, elastic modulus, and resistance to high-temperature, corrosion and erosion, etc. However, ceramic materials generally possess low toughness, low ductility and high crack damage sensitivity, which, combined with the high hardness and high melting temperatures, make them difficult to work with during the manufacturing. Fabricating ceramic components of arbitrarily complex shapes has been extremely challenging without 3D printing (Additive Manufacturing, AM). Furthermore, multi-material systems are often needed in order to develop functional components, which further adds challenges to conventional manufacturing.

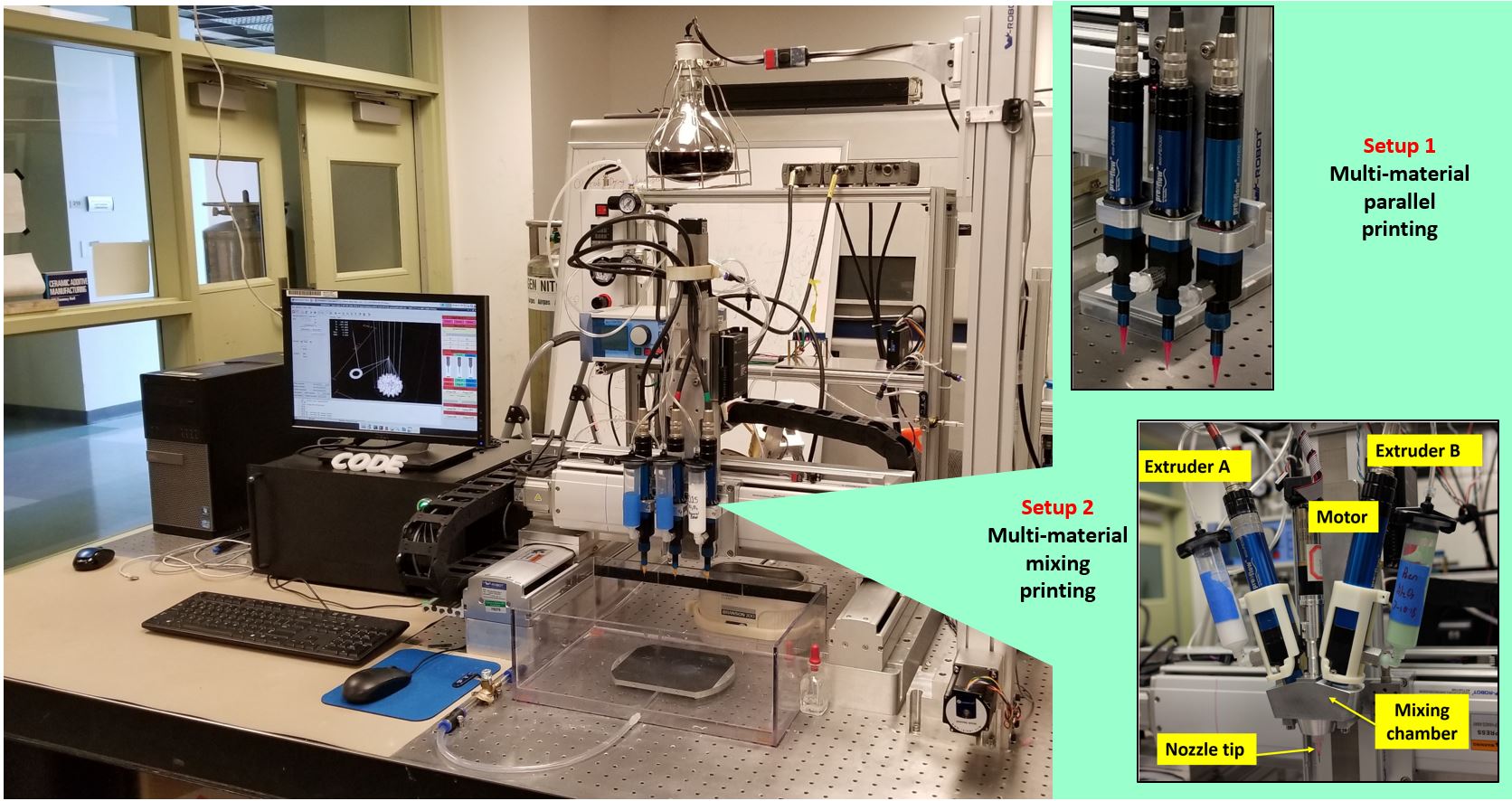

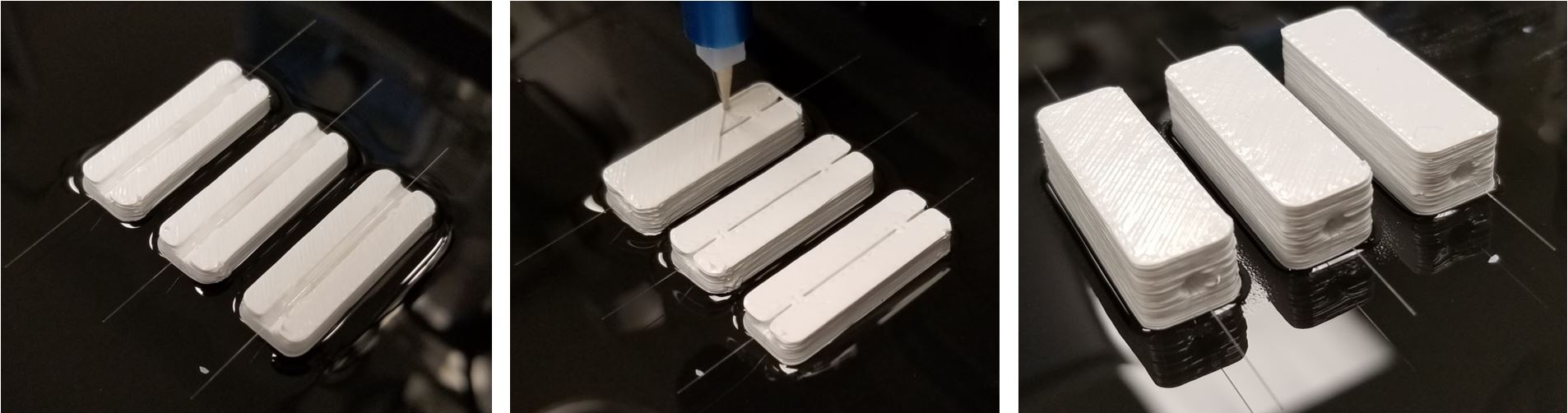

Material extrusion-based ceramic additive manufacturing is a subset of AM techniques that rely on the extrusion of viscous ceramic or ceramic precursor suspensions of suitable rheological behavior from a small nozzle, which is computer-controlled for layer-by-layer deposition to form 3D structures. It has been among the most popular approaches for freeform fabrication of ceramic components due to the simplicity and low cost of their fabrication system, high density of their fabricated parts, their capability of producing parts with multiple materials including functionally graded materials, and the low amount of material wasted during processing.

- 3D-printed ceramic components(see more at Portfolio-2, Portfolio-3, Portfolio-4)

Note: Sample 5 and 6 were printed with support material, 8 with graded material.

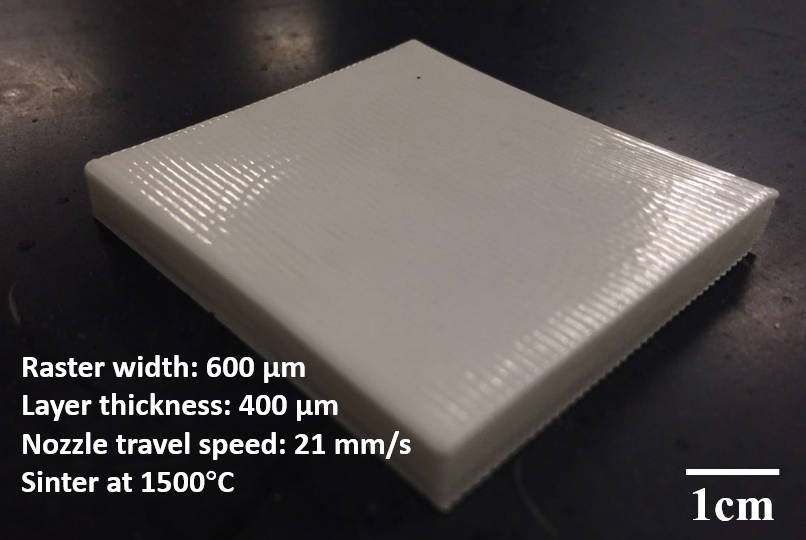

Note: Solid bulky sample printed from 3Y-TZP (3 mol% yttria stabilized tetragonal zirconia).

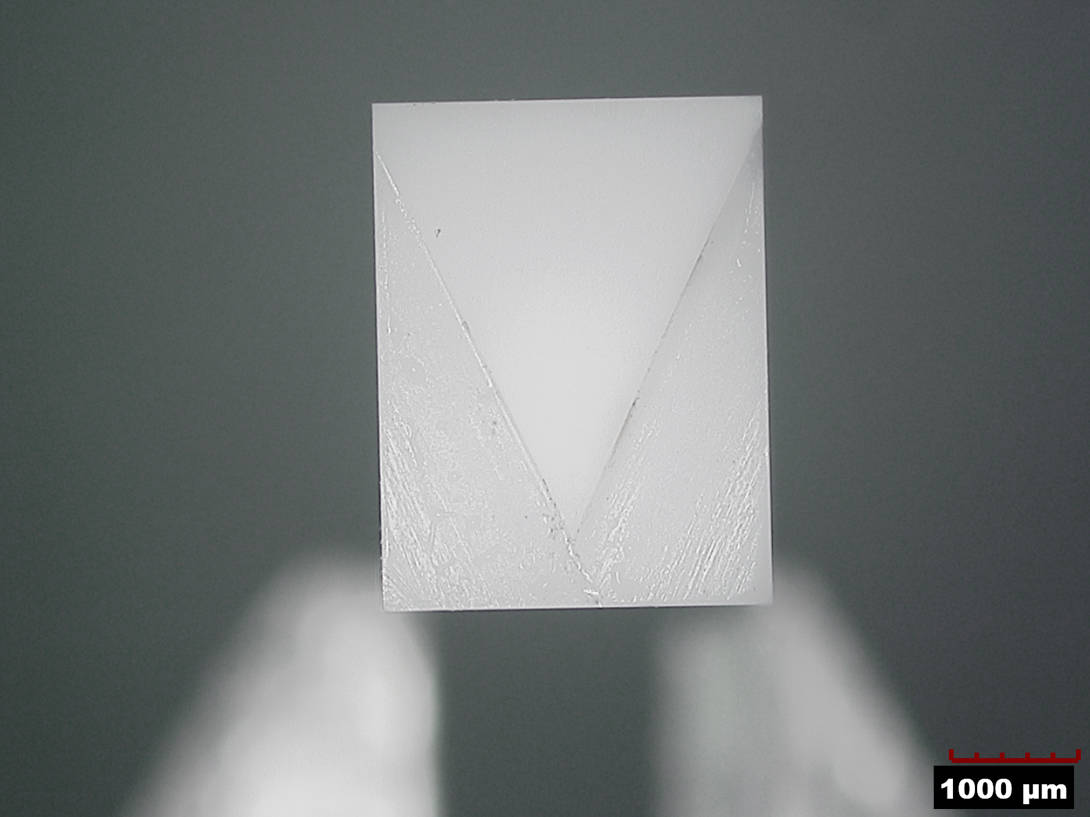

Note: Broken cross-section of the Chevron-Notched Beam made from a 3d-printed 3Y-TZP block.

Note: Fractography of the 3d-printed 3Y-TZP bars.

Note: Fractography of the 3d-printed 3Y-TZP bars.

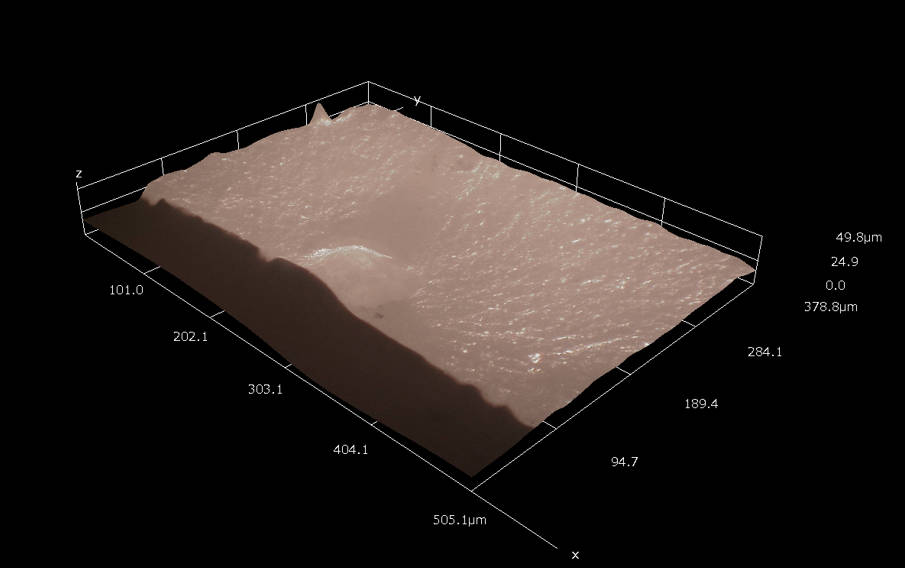

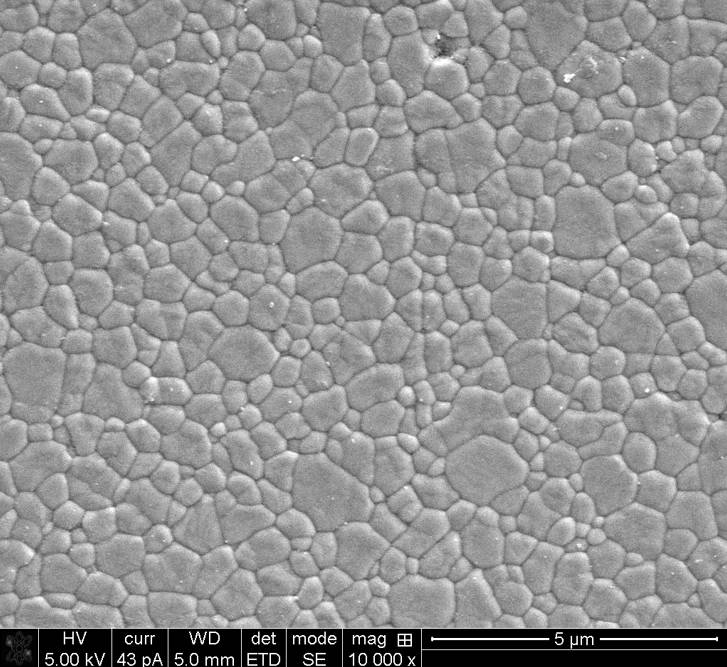

Note: Microstrucure of 3d-printed 3Y-TZP samples.

- 3D-printing with variable compositions (see device details and HD images at Portfolio-1, Portfolio-4)

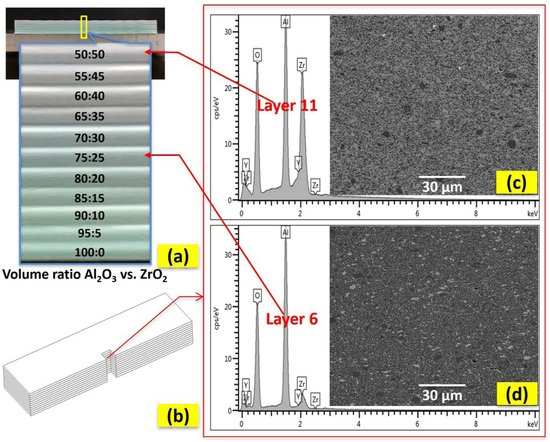

- A 11 layer Functionally Graded Materials (FGM) part.

- The 3D-Printing setup (see more details at Portfolio-1)

This research work is supported by the Kansas City National Security Campus (KCNSC, Managed by Honeywell) and also by the Intelligent Systems Center at Missouri University of Science and Technology.

Additive Manufacturing (AM) of Smart Parts with Embedded Sensors for In-Situ Monitoring in Advanced Energy Systems

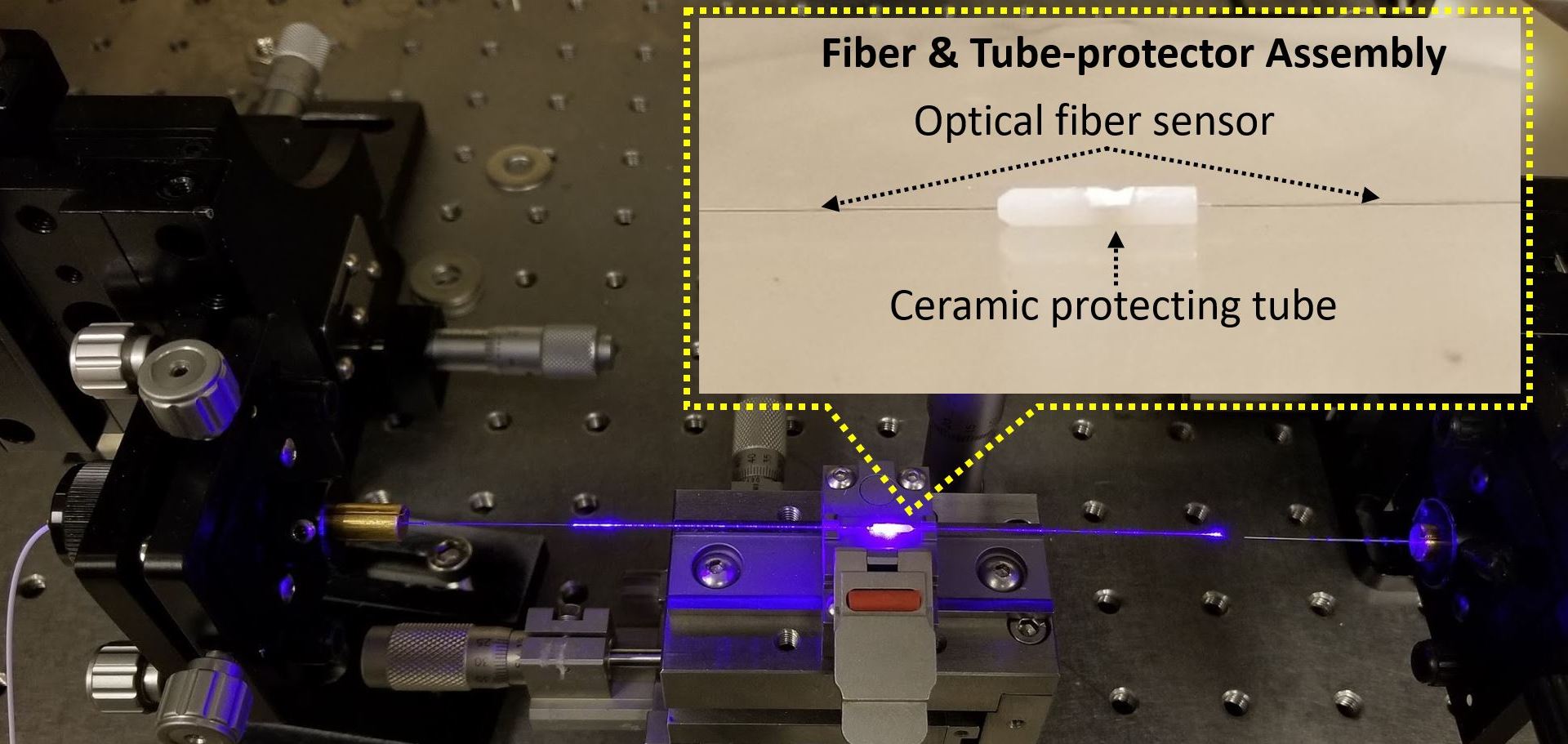

Embedded sensors have been widely used in structural health monitoring and proven very effective in civil and structural engineering. However, there are currently no viable techniques for in-situ monitoring of the health status of the critical components in energy production systems. In addition, the existing techniques for process monitoring are inadequate to operate reliably in the extremely harsh environments over a longtime. The sensing capabilities can be incorporated in the design phase of various energy systems by embedding sensors into the critical components, enabling a new paradigm in harsh-environment sensing. Embedded sensors are conventionally attached to or mounted on the component after the structure is fabricated.

Additive manufacturing (AM) is potentially a promising method that could be employed to embed the sensors into the host structure during the component fabrication. This allows secured sensor placement, enhances the survivability, improves the measurement accuracy and reliability, and preserves the structural integrity of the parts.

- Optical signal pass through the sintered fiber-tube assembly, signal energy loss (attenuation) measured:

- Embedding fiber-tube assembly into ceramic components during 3D-Printing:

More to be added.

This research work is supported by the U.S. Department Of Energy (DOE) and also by the Intelligent Systems Center at Missouri University of Science and Technology.

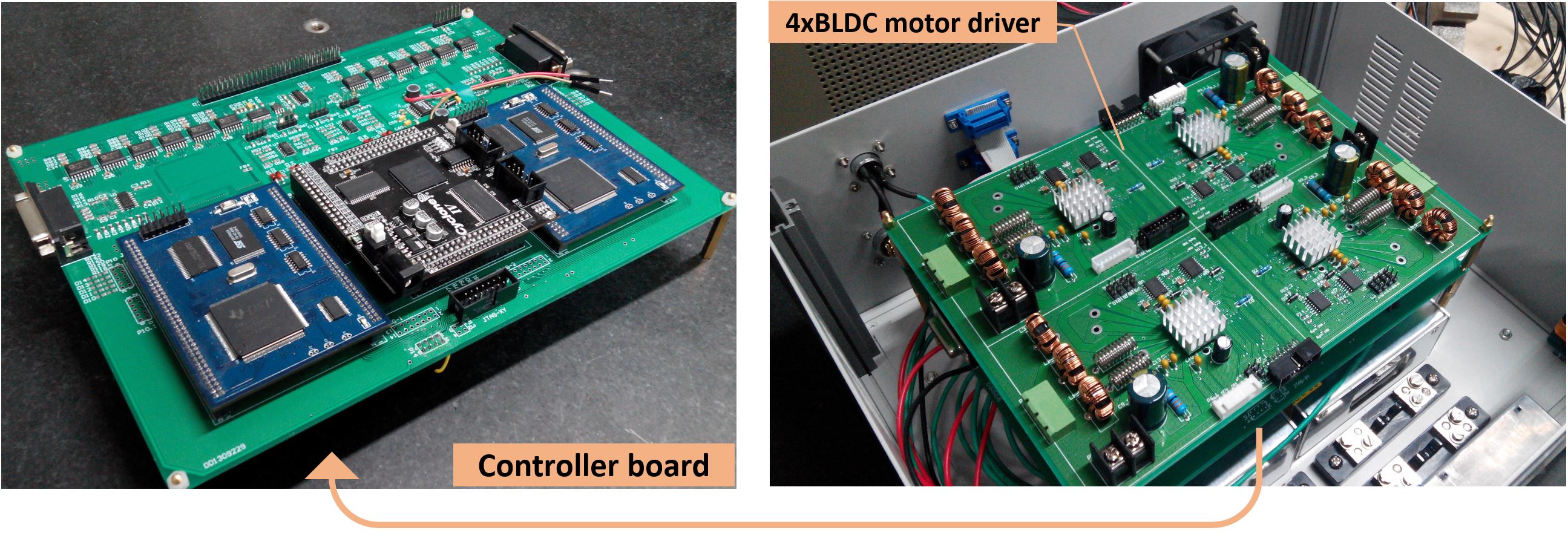

Embedded System Design Development, Servomotor Control

- Embedded system for 4-way servo-motor control in a high-precision positioning stage, 2011-2013

Self-driving Vehicle

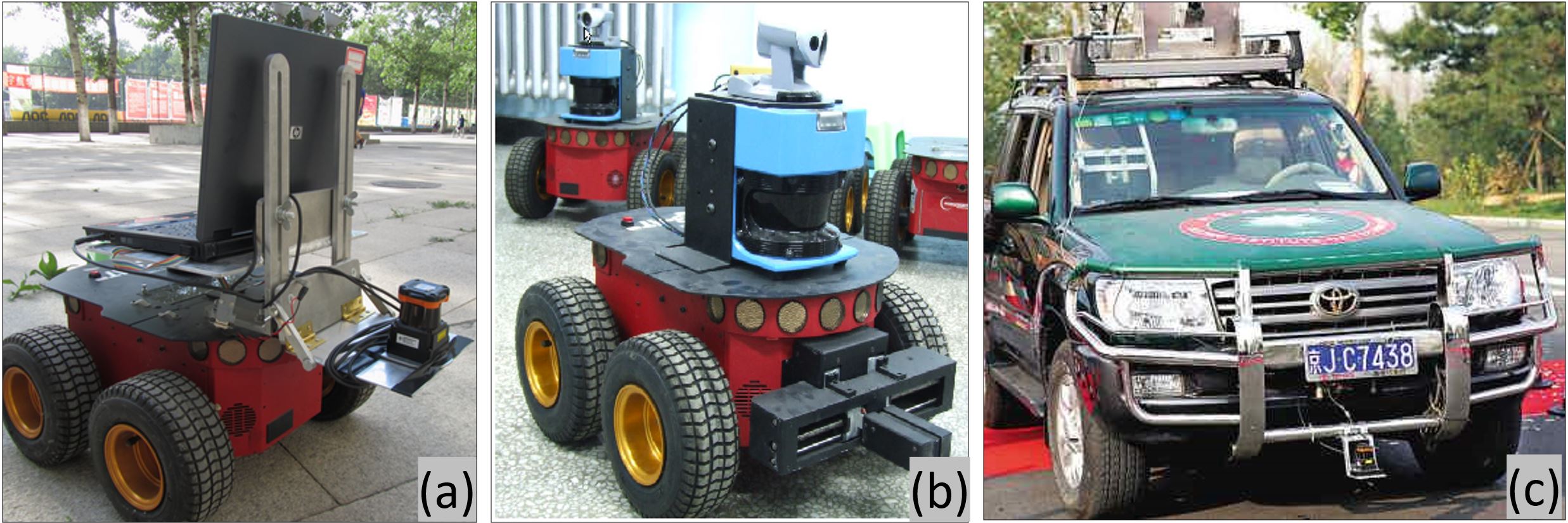

- Laser radars (Lidar) tested on wheeled robot, then employed on a SUV-based autonomous car, 2011

Racing Vehicle Prototyping (Student Formula Level)

- HONDA Eco Mileage Challenge 2009, 2010, Shanghai International Circuit, China

- Shell Eco-Marathon 2011, Sepang International Circuit, Malaysia

Publications

Books

ASM Handbook series chapter: Material Extrusion Based Ceramic Additive Manufacturing Chapter

Journal Papers

-

W. Li, A. Armani, A. Martin, B. Kroehler, A. Henderson, T. Huang, J. Watts, G. Hilmas, and M.C. Leu . “Extrusion-based additive manufacturing of functionally graded ceramics.” Journal of the European Ceramic Society 41, no.3: 2049-2057, 2021. Preprint Journal

-

W. Li, A. Armani, D. McMillen, M.C. Leu, G. Hilmas, and J. Watts. “Additive manufacturing of zirconia parts with organic sacrificial supports.” International Journal of Applied Ceramic Technology 17, no. 4: 1544-1553, 2020. Preprint Journal

-

W. Li, A. Ghazanfari, D. McMillen, M.C. Leu, G.E. Hilmas, and J. Watts “Characterization of Zirconia Specimens Fabricated by Ceramic On-Demand Extrusion”, , Ceramics International, 44(11), pp.12245-12252, 2018. Preprint Journal

-

W. Li, A. Ghazanfari, D. McMillen, M.C. Leu, G.E. Hilmas, and J. Watts, “Fabricating Ceramic Components with Dissolvable Support Structures by Ceramic On-Demand Extrusion Process”, CIRP Annals-Manufacturing Technology 66, pp. 225-228, 2017. Preprint Journal

-

W. Li, A. Ghazanfari, M.C. Leu, and R.G. Landers, “Extrusion-On-Demand Methods for High Solids Loading Ceramic Paste in Freeform Extrusion Fabrication”,Virtual and Physical Prototyping 12, pp. 193-205, 2017. Preprint Journal

-

X. Li, W. Li, F. Rezaei, and A. Rownaghi, “Catalytic Cracking of n-hexane for Producing Light Olefins on 3D-printed Monoliths of MFI and FAU Zeolites”, Chemical Engineering Journal 333, pp. 545–553, 2018.Preprint Journal

-

A. Ghazanfari, W. Li, M.C. Leu, J.L. Watts, G.E. Hilmas, “Additive Manufacturing and Mechanical Characterization of High Density Fully Stabilized Zirconia”, Ceramics International 43, pp. 6082–6088, 2017.Preprint Journal

-

A. Ghazanfari, W. Li, M.C. Leu, and G.E. Hilmas, “A Novel Freeform Extrusion Fabrication Process for Producing Solid Ceramic Components with Uniform Layered Radiation Drying”, Additive Manufacturing Journal 15, pp. 102-112, 2017. Preprint Journal

-

C. Murphy, K. Kolan, W. Li, J. Semon, D. Day, and M. Leu, “3D Bioprinting of Stem Cells and Polymer/bioactive Glass Composite Scaffolds for Tissue Engineering”, International Journal of Bioprinting 3 pp. 54–64, 2017.Preprint Journal

-

A. Ghazanfari, W. Li, M.C. Leu, J.L. Watts, and G.E. Hilmas, “Mechanical Characterization of Parts Produced by Ceramic On-Demand Extrusion Process”, International Journal of Applied Ceramic Technology 14, pp. 486-494, 2017. Preprint Journal

-

A. Ghazanfari, W. Li, M.C. Leu, Y. Zhuang, and J. Huang, “Advanced Ceramic Components with Embedded Sapphire Optical Fiber Sensors for High Temperature Applications”, Materials and Design 112, pp. 197-206, 2016.Preprint Journal

-

M. Li, A. Ghazanfari, W. Li, R.G. Landers, and M.C. Leu, “Modeling and Analysis of Paste Freezing in Freeze-Form Extrusion Fabrication of Thin-Wall Parts via a Lumped Method”, Journal of Materials Processing Technology 237, pp. 163-180, 2016. Preprint Journal

-

A. Ghazanfari, W. Li, and M.C. Leu, “Adaptive Rastering Algorithm for Freeform Extrusion Fabrication Processes”, Virtual and Physical Prototyping 10, pp. 163-172, 2015.Preprint Journal

Conference Papers

-

W. Li, A.J. Martin, B. Kroehler, A. Henderson, T. Huang, J. Watts, G.E. Hilmas, and M.C. Leu, Fabricating Functionally Graded Materials by Ceramic On-Demand Extrusion with Dynamic Mixing, pp. 1087-1099 in Proceedings of the 29th Annual International Solid Freeform Fabrication (SFF) Symposium. Edited by D.L. Bourell, R.H. Crawford, C.C. Seepersad, J.J. Beaman, and S. Fish. The University of Texas at Austin, Austin, TX, August 2018.Preprint

-

K. CR Kolan, W. Li, R. Althage, J. A. Semon, D. E. Day, and M.C. Leu. “Solvent and melt based extrusion 3D printing of polycaprolactone bioactive glass composite for tissue engineering.” pp. 14-17. in Proceedings of the 3rd International Conference on Progress in Additive Manufacturing (Pro-AM 2018). Edited by C.K. Chua, W.Y. Yeong, M.J. Tan, E. Liu, Singapore, May 2018. Preprint

-

W. Li, A. Ghazanfari, D. McMillen, M.C. Leu, and G.E. Hilmas, Fabricating Zirconia Parts with Organic Support Material by the Ceramic On-Demand Extrusion Process, pp. 606-615 in Proceedings of the 28th Annual International Solid Freeform Fabrication (SFF) Symposium. Edited by D.L. Bourell, R.H. Crawford, C.C. Seepersad, J.J. Beaman, and S. Fish. The University of Texas at Austin, Austin, TX, August 2017.Preprint

-

A. Ghazanfari, W. Li, M.C. Leu, and G.E. Hilmas, A Novel Extrusion-Based Additive Manufacturing Process for Ceramic Parts, pp. 1509-1529 in Proceedings of the 27th Annual International Solid Freeform Fabrication (SFF) Symposium. Edited by D.L. Bourell, R.H. Crawford, C.C. Seepersad, J.J. Beaman, and S. Fish. The University of Texas at Austin, Austin, TX, August 2016.Preprint

-

W. Li, A. Ghazanfari, D. McMillen, M.C. Leu, G.E. Hilmas, and J.L. Watts,Properties of Partially Stabilized Zirconia Components Fabricated by the Ceramic On-Demand Extrusion Process, pp. 916-928 in Proceedings of the 27th Annual International Solid Freeform Fabrication (SFF) Symposium. Edited by D.L. Bourell, R.H. Crawford, C.C. Seepersad, J.J. Beaman, and S. Fish. The University of Texas at Austin, Austin, TX, August 2016. Preprint

-

D. McMillen, W. Li, M.C. Leu, G.E. Hilmas, and J.L. Watts, Design Extrudate for Additive Manufacturing of Zirconium Diboride by Ceramic On-Demand Extrusion, pp. 929-938 in Proceedings of the 27th Annual International Solid Freeform Fabrication (SFF) Symposium. Edited by D.L. Bourell, R.H. Crawford, C.C. Seepersad, J.J. Beaman, and S. Fish. The University of Texas at Austin, Austin, TX, August 2016.Preprint

-

C. Murphy , K.C.R. Kolan , M. Long , W. Li , M.C. Leu , J.A. Semon , and D.E. Day, 3D Printing of a Polymer Bioactive Glass Composite For Bone Repair, pp. 1718-1731 in Proceedings of the 27th Annual International Solid Freeform Fabrication (SFF) Symposium. Edited by D.L. Bourell, R.H. Crawford, C.C. Seepersad, J.J. Beaman, and S. Fish. The University of Texas at Austin, Austin, TX, August 2016.Preprint

-

A. Ghazanfari, W. Li, M.C. Leu, J.L. Watts, Y. Zhuang, and J. Huang, Freeform Extrusion Fabrication of Advanced Ceramic Components with Embedded Sapphire Optical Fiber Sensors, pp. V001T04A014 in Proceedings of ASME Conference on Smart Materials, Adaptive Structures and Intelligent Systems, Stowe, VT, September 2016.Preprint

-

W. Li, A. Ghazanfari, M.C. Leu, and R.G. Landers, Methods of Extrusion on Demand for High Solids Loading Ceramic Paste in Freeform Extrusion Fabrication, pp. 333-345 in Proceedings of the 26th Annual International Solid Freeform Fabrication (SFF) Symposium. Edited by D.L. Bourell, R.H. Crawford, C.C. Seepersad, J.J. Beaman, and S. Fish. The University of Texas at Austin, Austin, TX, August 2015.Preprint

-

A. Ghazanfari, W. Li, M.C. Leu, and R.G. Landers, Planning Freeform Extrusion Fabrication Processes with Consideration of Horizontal Staircase Effect, pp. 1313-1323 in Proceedings of the 26th Annual International Solid Freeform Fabrication (SFF) Symposium. Edited by D.L. Bourell, R.H. Crawford, C.C. Seepersad, J.J. Beaman, and S. Fish. The University of Texas at Austin, Austin, TX, August 2015.Preprint

-

A. Ghazanfari, W. Li, M.C. Leu, and R.G. Landers, Optimal Rastering Orientation in Freeform Extrusion Fabrication Processes, pp. 1324-1333 in Proceedings of the 26th Annual International Solid Freeform Fabrication (SFF) Symposium. Edited by D.L. Bourell, R.H. Crawford, C.C. Seepersad, J.J. Beaman, and S. Fish. The University of Texas at Austin, Austin, TX, August 2015.Preprint

Google Scholar for a full list.

Reviews

Reviewed articles for:

- Virtual and Physical Prototyping

- Rapid Prototyping Journal

- Ceramics International

- Journal of Materials Science

- Journal of Alloy and Compounds

- International Journal of Bioprinting

- Journal of Sensors

- Sensors

- Metals

- IET Wireless Sensor Systems

- The Annual International Solid Freeform Fabrication (SFF) Symposium

Awards

Received:

- Dean’s Ph.D. Scholar, College of Engineering and Computing, Missouri S&T, 2018

- Best Presentation Award, Annual Missouri S&T ISC Graduate Research Symposium, 2018

- Top 10 Most Downloaded Papers, Journal of Applied Ceramic Technology, 2017

- NSF Student Travel Award, 2016

- Best Paper Award, ASME Symposium on Integrated Systems Design and Implementation, 2016

- 2nd Best Presentation Award, Annual Missouri S&T ISC Graduate Research Symposium, 2015

- 2nd Best Poster Award, Annual Missouri S&T ISC Poster Presentation, 2014

- 3rd rank among 131 teams in the 4th HONDA Econo-power Car Competition, team leader, 2010

- TOYOTA Scholarship by Toyota Motor Corporation, 2009

- 1st rank among 120 teams in the 3rd HONDA Econo-power Car Competition, 2009

Service Activities

Served for:

- Volunteer, China International Industry Fair (CIIF), Sep. 15-19, 2020

- Volunteer, RoboBusiness 2019, Santa Clara, CA, Oct. 2-3, 2019

- Laboratory tour guide for visitors Profs. Jihong Yan and Chaozhong Guo from Harbin Institute of Technology, Oct. 5, 2018

- Presenting for Missouri S&T Industry Day, Sep. 25, 2017

- Mentoring student from the REU program, Summer, 2015

Portfolio

Portfolio:

- Customized 3D Printers for Various Research Topics

- Single-material Ceramic Components

- Ceramic Components Printed with Using Support Material

- Ceramic Components Printed with Varying Material Composition/Color

Certificates:

- System Control and Dynamics (Udemy)

- Data Analysis with Pandas (Udemy)

- Neural Networks and Deep Learning (Coursera)

- Improving Deep Neural Networks: Hyperparameter tuning, Regularization and Optimization (Coursera)

Hobby

- Badminton